Industries we serve for Systems Integrations and Machine Building

We Work In All Industries

Industries We Serve with Systems Integration & Machine Building

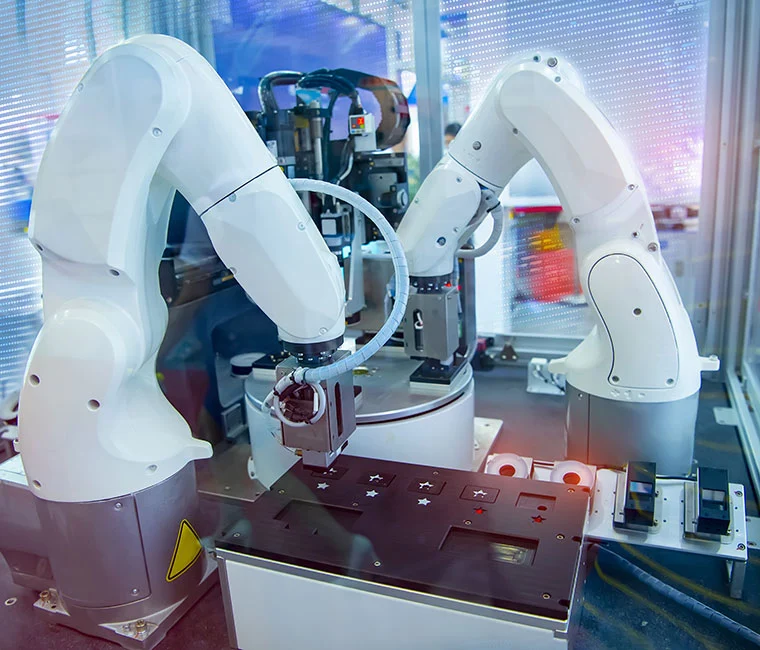

From assembly automation to process design, controls engineering, and software integrations—our team has built custom solutions for nearly every application, process, and industry.

Tier 1 & tier 2

Automotive

Cardinal has been a supplier to the automotive industry since our inception 50 years ago. We've helped companies like Joyson Safety Systems, Atlantic Research Corporation, Nexteer, American Axle and Manufacturing, and others with machine building and systems integration.

Our strength is our ability to provide robust turn-key systems. We are also able to rebuild and retool existing machines so customers get the most value from their original investments.

Why Choose Cardinal?

Why choose us for automotive machine building and systems integration?

- Our experience, reputation, quality and commitment. We get the job done right and we never walk away from a difficult assignment.

- We are financially strong and debt-free.

- We have a dedicated team with minimal turnover. Our current VP of Operation started with us as an intern 20 years ago!

- We have unique expertise in key areas. We specialize in product and process launches.

- We provide turnkey systems and solutions.

- We understand manufacturing and know how to provide solutions that fit into existing processes.

- We provide personal attention. You can call us anytime day or night.

ensuring safety & efficiency

Medical & Life Sciences

The way medical devices, pharmaceutical products, or protective equipment is manufactured these days is rapidly changing. Medical manufacturing and material-handling processes need to meet rigorous safety and verification standards, as well as be fast, efficient, flexible, and accurate.

Automation systems streamline these processes and improve overall production performance.

How Medical Equipment Manufacturers Benefit

Our experience with high-volume manufacturing processes ensures precision and repeatability for medical equipment producers. We provide custom assembly and automation systems that help you:

- Bring product innovations to market faster

- Create a more efficient production or delivery line

- Increase process quality

- Ensure compliance and validation

- Drive standardization across multiple locations and teams

Our Medical Equipment Capabilities

Our specific services and capabilities include:

- Build-to-customer-print capabilities

- Special machine building

- Packaging equipment build and automation

- Weld tooling and robotic welding cells to manufacture products such as stretchers, hospital beds and other medical equipment, as we have done for Stryker Corporation

- Process development

- Spare parts and commodities

meeting consumer demand

Home/Consumer Goods

From footwear to household goods, automation is an important contributor to the manufacturing of consumer goods. Automated equipment is ideal for completing repetitive tasks like moving parts across stations, applying sealants, and joining materials. Four- or six-axis robots can assemble and move pieces along an assembly line and through different stations efficiently.

At Cardinal, we have nearly two decades of experience helping brands like Closet Maid and others meet their production needs with automation, robotics, and custom machines.

How Consumer Goods Manufacturers Benefit

Cardinal's automation and system integration solutions help you:

- Stay within budget.

- Meet deadlines. Cardinal specializes in product and/or process launches.

- Meet quality requirements.

- Meet production requirements.

- Solve problems. We are not just order takers. We are a solutions provider.

- Work with a turnkey supplier. In addition to new builds, we provide ongoing maintenance and troubleshooting and optimization.

Our Consumer Goods Capabilities

Our specific services and capabilities for consumer good manufacturers include:

- Build-to-customer-print capabilities

- Special machines

- Packaging lines

- Tooling

- Process development

- Spare parts and commodities

first-response capabilities

Emergency Vehicles

Whereas automotive manufacturers are challenged with maintaining high production levels, emergency vehicle manufacturers operate in a low-volume environment. Automakers produce millions of units per year. By contrast, emergency vehicle makers might produce hundreds or maybe thousands of units annually.

This low volume context requires a different mindset when it comes to equipment and tooling. At Cardinal, we are experienced working in this context, having performed machine building for companies like E-One for more than a decade.

How Emergency Vehicle Makers Benefit

Cardinal's automation and system integration solutions help emergency vehicle manufacturers:

- Stay within budget.

- Meet deadlines. Cardinal specializes in product and/or process launches.

- Meet quality requirements.

- Meet production requirements.

- Solve problems. We are not just order takers. We are a solutions provider.

- Work with a turnkey supplier. In addition to new builds, we provide ongoing maintenance and troubleshooting and optimization.

Our Emergency Vehicle Services Capabilities:

- Special Machines

- Weld Tooling

- Robotic Welding Cells

- Assembly Fixtures

- Process Development

- Spare Parts and Commodities

battlefield ready

Defense/Military

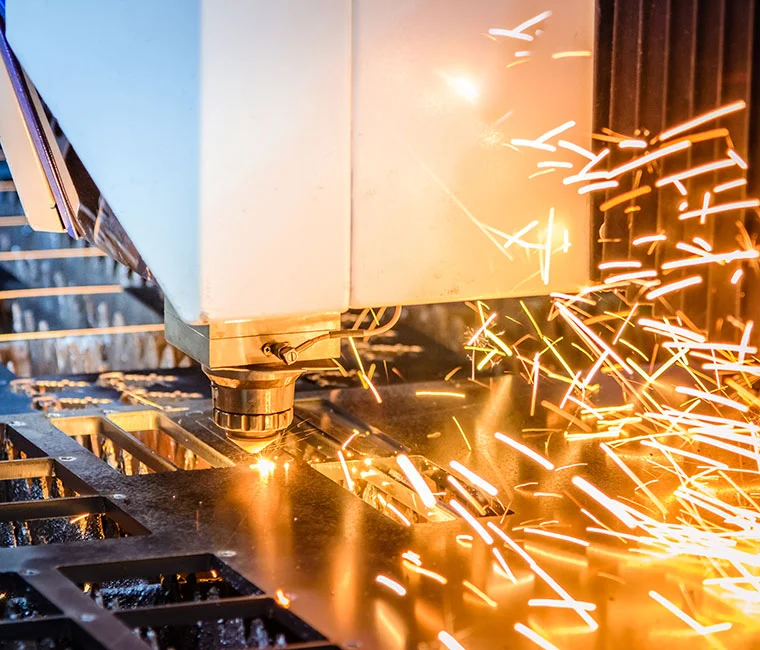

Automation in the defense industry includes using advanced technology to assemble aircraft components, weaponry or ammunition at higher speeds and higher quality than manual labor alone.

Defense automation solutions can include robotics, vision, conveyance, gantry systems, and more. Automated technologies can ensure that parts meet strict quality and repeatability standards.

Cardinal has a decade of providing tooling and equipment to defense contractors such as Modineer, who supplies metal components and assemblies to the military vehicle market.

How Defense Contractors Benefit

Our experience with high-volume manufacturing processes ensures precision and robustness for defense contractors. We are a turnkey supplier with vast in-house capabilities and experience. We help you:

- Stay within budget.

- Meet short deadlines.

- Meet strict quality and performance requirements.

- Comply with Federal contracts.

- Solve problems and optimize processes.

- Personal attention and service.

Our Defense Capabilities

Our specific services and capabilities include:

- Weld tooling

- Robotic weld cells

- Special machines

- Tooling

- Process development

- Spare parts and commodities

off-road & ON-road

Recreational Vehicles

Recreational vehicle manufacturers like golf cart maker Yamaha have turned to Cardinal machine building for over 10 years.

If you are a recreational vehicle manufacturer, we can help you, too. From golf carts to ATVs, we have the experience to improve processes and support production with welding, custom specialty machines and more.

How Recreational Vehicle Manufacturers Benefit

Cardinal's automation and system integration solutions help you:

- Stay within budget.

- Meet deadlines. Cardinal specializes in product and/or process launches.

- Meet quality requirements.

- Meet production requirements.

- Solve problems. We are not just order takers. We are a solutions provider.

- Work with a turnkey supplier. In addition to new builds, we provide ongoing maintenance and troubleshooting and optimization.

Our Recreational Vehicle Capabilities

Our specific services and capabilities for consumer good manufacturers include:

- Weld tooling

- Robotic Weld Cells

- Special Machines

- Tooling

- Process Development

- Spare Parts and Commodities

robust turnkey solutions

Chemical

Cardinal has been a supplier to chemical companies like Dow Chemical for over a decade, supporting them with robust turnkey system integration and machine building services, including new machine builds, machine maintenance and repairs, automation, and specialty machines.

How We Help Chemical Companies

Many chemical companies have minimal in-house mechanical engineering and machine building capabilities. We supply the expertise they need. Our capabilities include:

- Build-to-customer-print capabilities.

- Special machines.

- Tooling.

- Process development.

- Spare parts and commodities.

Our Chemical Capabilities

Our specific services and capabilities for chemical companies include:

- Weld tooling

- Robotic Weld Cells

- Special Machines

- Tooling

- Process Development

- Spare Parts and Commodities

building & growing

Construction/Agriculture Heavy Equipment

Construction and agricultural equipment companies automate their assembly lines to manufacture everything from trucks and tractors to earthmovers and cranes. Building heavy equipment like this brings a set of challenges unlike most other industries. Size and scale take precedence, as does safety.

At Cardinal, we have helped companies like Caterpillar and Woods Equipment automate their processes to improve production and increase efficiency and safety. We can support the production of skid steers, crawlers, articulated dump trucks, graders, front loaders, and more, using automated MIG welding, laser welding, pick-and-place robots, vision systems, and more.

How heavy Equipment Manufacturers Benefit

Our experience with high-volume manufacturing processes ensures precision and robustness for heavy equipment makers. We are a turnkey supplier with vast in-house capabilities and experience. We help you:

- Stay within budget.

- Meet short deadlines.

- Meet strict quality and performance requirements.

- Comply with Federal contracts.

- Solve problems and optimize processes.

- Personal attention and service.

Our Heavy Equipment Capabilities

Our specific services and capabilities include:

- Build-to-customer-print capabilities

- Special Machines

- Tooling

- Weld Tooling

- Robotic Welding Cells

- Process Development

- Spare Parts and Commodities